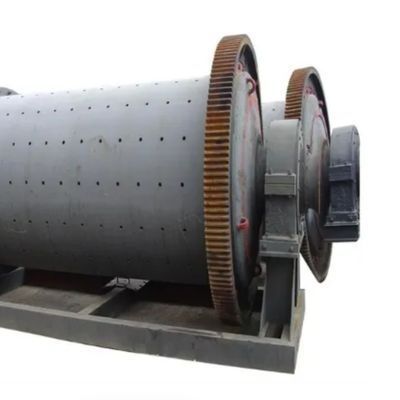

Beschreibung des Produkts

Die Stangemühle ist eine Art Materialfeinbrenn- und Schleifgeräte, die in Industriezweigen wie Bergbau, Baustoffe, Chemie und Energie weit verbreitet sind.

Arbeitsprinzip

Die Stange besteht hauptsächlich aus dem Zylinder, dem Hauptlager, der Basis, dem großen Getriebe, dem kleinen Getriebe, dem Schraubblatt, dem Flansch, dem Lager, der Hohlwelle usw. Im Inneren des Zylinders befindet sichStahlstangen als Schleifmedien installiertDie Materialien werden durch die Stahlstangen im Inneren des Zylinders gemahlen und zerkleinert und durch Überlauf oder kontinuierliche Zufuhr für den nächsten Prozeß entladen.

Leistungsvorteilvon Erzschleifwerken

Hohe Leistung und gute Entladung: Das Schleifen von Materialien durch das Stange-Schleifmedium ändert sich vom Oberflächenkontakt zum Linienkontakt, was zu einer gleichmäßigen Entladung und einer höheren Leistung führt.

Energieeinsparung: Verglichen mit der alten Stange kann sie etwa 50% Energie einsparen und somit den Energieverbrauch sparsamer machen.

Umweltschonende Produktion: Die Konstruktion verringert die Ausstrahlung von Staub, vermeidet Umweltverschmutzung und ermöglicht eine umweltfreundliche Produktion.

Lange Lebensdauer: Die anfälligen Teile und Kernkomponenten sind aus hochwertigen Materialien gefertigt, was die Lebensdauer der Ausrüstung um mehr als das Dreifache verlängert.

Anwendungsbereichvon Erzschleifwerken

Bergbau: Es wird zum Zerkleinern und Schleifen von Erzen verwendet und liefert Grundrohstoffe für spätere Prozesse wie die Mineralverarbeitung und Schmelze.

Bauindustrie: In der Zementproduktion wird es zum Schleifen von Rohstoffen wie Kalkstein und Ton verwendet, um die Qualität des Zements zu verbessern.Erzeugen von Sand und Kies, die den Anforderungen des Baus entsprechen.

Stahlherstellung: Es wird für das Grobschleifen von Erzen und die Verarbeitung von Rohstoffen im Stahlproduktionsprozess verwendet, um die Qualität der Rohstoffe zu gewährleisten.

Merkmalvon Erzschleifwerken

- Die zylindrische Mühle verwendet den Antriebstypen Randantrieb, Mittelantrieb, Randantrieb mit Mehrpunktenmaschen usw.mit einem Asynchronmotor-Reduktor-Zug und einem Getriebe sowie einem synchronen Motor-Luftkupplungs-Zug und einem Getriebe.

- Generell mit einem statisch-dynamischen Drucklager an beiden Enden.Auch einzelne oder doppelte Slipper-stabil-dynamische Lager können verwendet werdenDer Busch wird von NC-Maschine gemacht.

- Das große offene Getriebe ist nach dem AGMA-Standard konstruiert, ausgestattet mit einem zuverlässig versiegelten Getriebegehäuse und einem automatischen Schmiersystem mit Fettbeschichtung.

- Die Schale ist ein wesentlicher Bestandteil einer Mühle, die mit Hilfe eines Computers analysiert wird, um einen zuverlässigen Betrieb zu gewährleisten.

- Die Hülle wird automatisch geschweißt, mit Ultraschall geprüft, vollständig gegrillt und mit großen speziellen Werkzeugmaschinen auf einem Schlag bearbeitet.ch als Futter- und Entladungs-Hopper, Trunnion usw. zur Verhinderung von Öl- und Schlammlecks;

- Die Auskleidung besteht aus einem verschleißfestem Material, das von unserer Firma hergestellt wurde und speziell hitzebehandelt wurde, mit hoher Härte und langer Lebensdauer.Auch andere verschleißfeste Gusse oder Gummifolien können verwendet werden;

- Es gibt langsame Geschwindigkeitsantriebe für mittlere und große Mühlen;

- Die Schmierstation mit hohem und niedrigem Druck ist für mittlere und große Mühlen ausgestattet.

- Das Steuerungs- und Schutzsystem wird durch PLC gesteuert.

Technische Parameter der Erzschleifmühle

| Modell |

Durchmesser des Zylinders

(mm) |

Zylinderlänge

(mm) |

Wirkungsvolumen

(m3) |

Geschwindigkeit der Mühle

(r/min) |

Belastung der Schleifmedien (t) |

Elektromotor |

Größe

(L × W × H)

(m) |

Gewicht

(T)

|

Motorleistung

(kW) |

Geschwindigkeit

(r/min) |

| MB15 × 30 |

1500 |

3000 |

5 |

23 |

8 |

75 |

743 |

7.6 mal 3,4 mal 2.8 |

20 |

| MB17 × 30 |

1700 |

3000 |

5.8 |

20 |

10.2 |

90 |

980 |

7.6 mal 3,5 mal 3.1 |

40.4 |

| MB21 × 30 |

2100 |

3000 |

8.8 |

19.4 |

25 |

220 |

735 |

8.7 mal 4.8 mal 4.4 |

48 |

| MB21 × 36 |

2100 |

3600 |

10.8 |

21 |

28 |

220 |

735 |

9.5 mal 4 mal 4.7 |

52.5 |

| MB24 × 30 |

2400 |

3000 |

11.8 |

18.2 |

27 |

250 |

735 |

8.5 mal 4,2 mal 4.6 |

58 |

| MB27 × 36 |

2700 |

3600 |

18.8 |

17.5 |

42 |

400 |

187 |

12 mal 5,7 mal 4.7 |

70 |

| MB30 × 40 |

3000 |

4000 |

25.9 |

16.2 |

50 |

500 |

187 |

12.6 mal 6.1 mal 4.9 |

89 |

| MB32×45 |

3200 |

4500 |

33 |

15.5 |

56 |

630 |

167 |

16 mal 8 mal 5.6 |

111.5 |

| MB32×48 |

3200 |

4800 |

34 |

15.5 |

60 |

710 |

740 |

12 × 7 × 6 |

121.2 |

| MB36 × 54 |

3600 |

5400 |

50 |

14.5 |

97 |

1000 |

167 |

16 mal 8 mal 6.7 |

155 |

| MB38 × 52 |

3800 |

4200 |

54.1 |

14.2 |

102 |

1120 |

992 |

15 mal 8,27 mal 6.21 |

175 |

| MB38×58 |

3800 |

5800 |

60.3 |

14.2 |

112.2 |

1250 |

167 |

15.6 mal 8.27 mal 7.21 |

156 |

| MB40 × 60 |

4000 |

6000 |

70 |

14.0 |

130 |

1400 |

200 |

18.2 mal 9.00 mal 7.5 |

163 |

Produktanzeige der Erzschleiferei

Häufig gestellte Fragen

F: Warum glauben wir an die Luoyang Zhongtai Industries Co., Ltd.:

A: 1. Mehr als 30 Jahre Erfahrung.

2Wir sind der führende professionelle Anbieter von Bergbaumaschinen, Baumaschinen, Gießmaschinen und geschmiedeten Teilen

3Alle Produkte haben ein ISO9901:2000 Qualitätsmanagement-Zertifikat und CE- und ROHS-Zertifikate erhalten.

F: Lieferzeit

A: Die Lieferzeit für Teile beträgt 1-2 Monate, für Maschinen 2-3 Monate.

Q:Zahlungsbedingungen

A: Akzeptieren Sie Zahlungsart: T/T, L/C, Western Union, Bargeld.

30% Anzahlung bei Vertragsunterzeichnung

F: Qualitätsgarantie?

A: Garantiezeit: ein Jahr für die Hauptmaschine. Wenn etwas nicht stimmt, geben wir die technische Beratung und finden sofort eine Lösung.Für die Träger garantieren wir hochwertige Teile für die langfristige Lieferung..

F: Nachverkaufsservice?

A: Wir können technische Anleitungen für Maschinen liefern, die Tests durchführen, und für die Wartung von Teilen, wenn der Endbenutzer dies benötigt.

Dienstleistungen nach dem Verkauf

ZTIC Heavy Industries ist Ihr Geschäftspartner im Aftermarket.

ZTIC in der Lage:

1. Maschinenbauteile - Konstruktion und Herstellung

2. GROSSE GEWÄHLTE GEWÄHLER für Stahl und Eisen

3. ENORME Maschinenbaukapazitäten

4. Ausbildungsprogramme

5. Präventive Wartungsprogramme

6. PREVENTATIVE Wartungsleistungen

7. umfassende Wartungsprogramme

Die Ingenieure für den Außendienst von ZTIC sind speziell für die Produkte der CITIC-Markengruppe ausgebildet, können aber auch für die Wartung anderer OEM-Marken arbeiten.

Unsere Techniker verfügen über die fortschrittlichste diagnostische Ausrüstung, um Ihre Ausrüstung zu schießen, um die Leistung zu optimieren und die Ausfallzeiten zu minimieren.

ZTIC verfügt darüber hinaus über eine umfangreiche Kapazität zur Versorgung Ihrer Verbrauchsmaterialien und elektrischen/mechanischen Ersatzteilbedürfnisse.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!